PM 11, a former newsprint machine, was successfully rebuilt by Voith for the production of high-quality graphic paper. The machine now has the capacity to produce 520,000 tons per year.

PM 11, a former newsprint machine, was successfully rebuilt by Voith for the production of high-quality graphic paper. The machine now has the capacity to produce 520,000 tons per year.

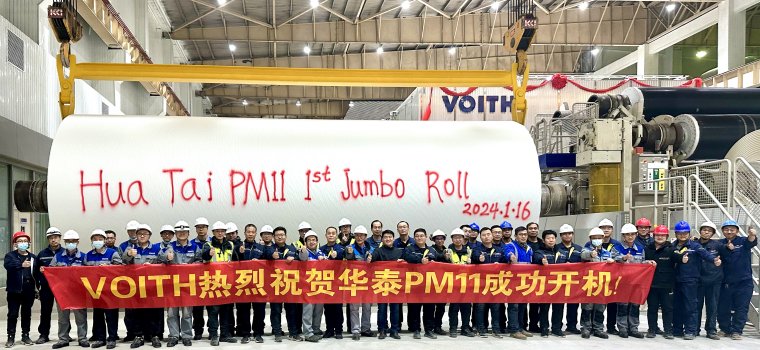

Jan. 29, 2024 - Shandong Huatai Paper and Voith Paper on January 16 successfully started up PM 11 in the eastern Chinese province of Shandong. PM 11, a former newsprint machine, was successfully rebuilt for the production of high-quality graphic paper. The machine's web width is 10.2 meters and the design speed 1,800 m/min.

With the help of leading Voith technologies, the annual capacity of the rebuilt PM 11 can be increased from 400,000 to 520,000 tons.

"The rebuild has not only transformed the almost 20-year-old paper machine into a modern paper machine, but has also significantly improved the machine's stability and capacity," said Wei Lijun, General Manager of Shandong Huatai Paper.

The customized rebuild of PM 11 includes a variety of state-of-the-art technology solutions with a focus on stability, reliability and efficiency. The solutions not only help to extend the service life but also lead to more sustainable and cost-efficient operation.

This involves upgrading the MasterJet Pro G headbox and implementing the optimization of dilution water technology to improve paper quality while reducing energy costs.

Voith also upgraded the forming section similar to the DuoFormer concept for optimum formation and higher throughput. In addition, the ParaSlice nozzle concept and the EdgeModule system were integrated to stabilize the fiber orientation profile (CD profile). The newly installed ProRelease+ HighEnd boxes in the pre-dryer section significantly increase the vacuum level to 3000 Pa, ensuring the stability of the paper web at high speeds and minimizing the risk of paper breaks.

In addition, a SpeedSizer AT with its uniform film application ensures even and high-quality paper profiles. The CombiDuoRun dryer concept and an efficient new dryer section hood are used in the after-dryer section.

By installing digital solutions from the Papermaking 4.0 portfolio, in particular the OnQuality quality management system (QCS) and the OnControl automation technology (MCS), the PM 11 has been brought up to date, resulting in a significant increase in operating convenience and control stability, Voith said.

Voith Paper, part of the Voith Group, is the full-line supplier to the paper industry, providing a wide range of technologies, services, components and products, and offers paper manufacturers solutions from a single source.

SOURCE: Voith

Paper Industry Newsletter

Stay on top of paper industry news

from around the world with

PaperAge's free weekly newsletter.

Delivered every Thursday.

Sign up today!